Over 10 years we help companies reach their financial and branding goals. Engitech is a values-driven technology agency dedicated.

411 University St, Seattle, USA

engitech@oceanthemes.net

+1 -800-456-478-23

Welcome to our guide on maintaining power equipment designed and manufactured by Sinepower. Whether you’re using GPUs (Ground Power Unit) or SFCs (Static Frequency Converter), proper maintenance is essential to ensure optimal performance, longevity, and reliability. In this article, we’ll cover some essential maintenance tips and best practices that will help you get the most out of your power equipment investment.

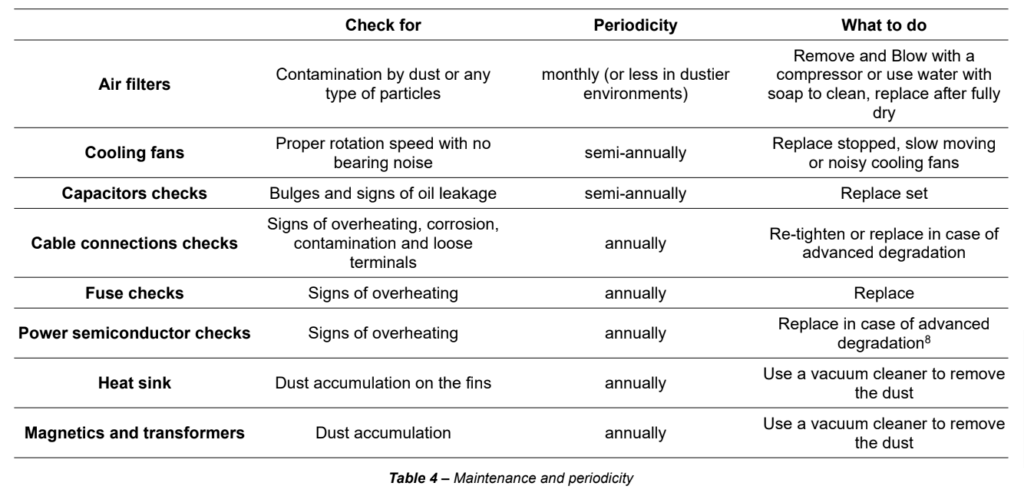

As you know by now, maintenance is a critical aspect of ensuring the longevity and efficient operation of any system, equipment, or infrastructure. Two fundamental approaches to maintenance, preventive and remedial maintenance, play pivotal roles in achieving this goal. Whether you aim to prevent problems before they occur or tackle existing issues swiftly, understanding these maintenance approaches is essential for optimizing the performance and lifespan of your assets.

Proper preventive maintenance is the key to optimal operation of the equipment and will ensure a long and useful life of the system. Preventive maintenance includes regularly performed procedures designed, as the name suggests, to prevent system malfunction and obtain maximum operational efficiency.

Remedial maintenance requires troubleshooting to repair the system. Troubleshooting the equipment involves following a logical sequence of steps which will determine the cause of an alarm and/or malfunction within the shortest time frame possible to expedite the repair and return of the equipment to normal service.

In order to safely and successfully perform maintenance on the equipment, certain safety precautions must be observed. Necessary tools, Personal Protective Equipment (PPE), and test equipment must be available. The following basic safety practices should always be practiced:

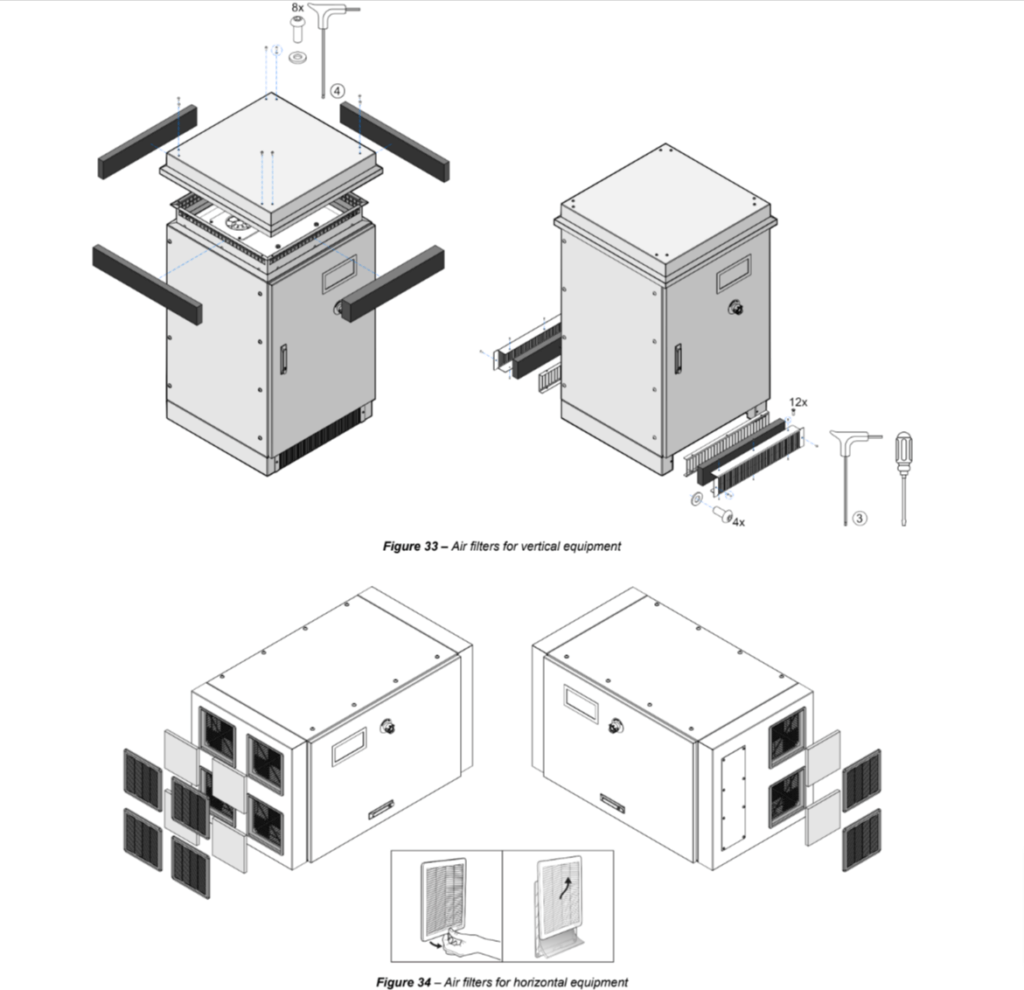

Throughout our technical guide for installation, commissioning, use and maintenance, we provide our clients with all the detailed instructions on how to maneuver our equipment for the best outcome. Here is one example of how we recommend dealing with our air filters:

By following these maintenance best practices, you can extend the lifespan of your power equipment, optimize performance, and reduce the risk of unexpected failures. Regular cleaning, power quality management, cable organization, and a well-structured preventive maintenance schedule are all essential components of a successful maintenance strategy. Investing time and effort into proper maintenance will pay off in the form of increased equipment reliability and productivity for years to come.

Fill in the form and our technical team will assist you as soon as possible.